Team Protrak is heading to Build Expo 2026 — Tampa

See how leading precast teams are digitizing element tracking, production & site execution.

Meet us at

Booth #432

From

4-6 Feb 2026

Platform & Solutions by Prorigo

Team Protrak is heading to Build Expo 2026 — Tampa

See how leading precast teams are digitizing element tracking, production & site execution.

Meet us at

Booth #432

From

4-6 Feb 2026

Gate by Gate.

Protrak's APQP solution digitizes every phase — from RFQ to SOP — with full traceability, cross-functional visibility, and audit readiness. No more missed gates. No more spreadsheet sprawl.

Automotive APQP (Advanced Product Quality Planning) is designed to bring rigor and discipline to new product development. But in real-world scenarios, it often ends up looking like this:

Teams work in isolation, leading to misalignment and delays across the APQP lifecycle.

Without a centralized system, tracking gate status and ownership becomes guesswork.

Coordinating inputs and approvals with suppliers is slow and lacks structure.

Version control for DFMEAs, quotations, process flow, control plans, and PPAP documents is often inconsistent and audit-unready.

Spreadsheets and emails dominate planning and documentation, making processes time-consuming, prone to errors, and causing avoidable delays.

As projects grow, manual APQP processes become unmanageable and error-prone.

Protrak eliminates the complexity and fragmentation of traditional APQP processes by offering a centralized, low-code platform tailored for automotive manufacturers.

Manage the entire APQP lifecycle — from RFQ to SOP — in a single, connected system.

Unite NPD, QA, Purchase, Marketing, HR, Production and Management teams with shared workflows and live updates.

Automate milestone tracking, set reminders, and ensure on-time approvals.

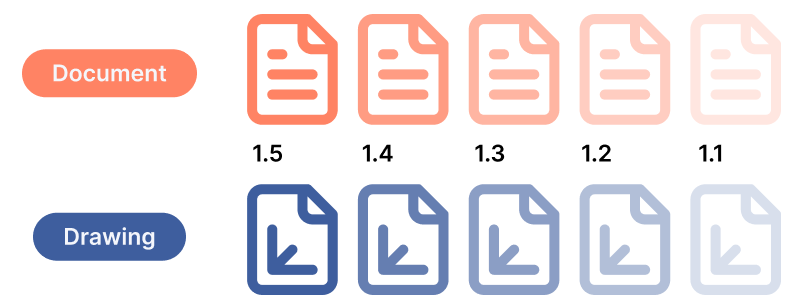

Store and manage DFMEAs, quotations, feasibility reports, process flows, control plans, and PPAP docs with full version history.

DFMEA_EngineMount_V1.pdf

NPD

Version: 1.0

Collaborate seamlessly with suppliers and customers via secure, role-based access.

Gain real-time visibility into gate status, documentation, and audit readiness.

Capture and organize part enquiries and RFQs in a centralized system with full traceability.

Form project-specific teams with defined roles and automate multi-level approvals.

Evaluate commercial, technical, and risk feasibility to ensure project viability from the start.

Assess process flows, raw material requirements, drawing feasibility, deviations, and change requests to validate manufacturability.

Standardize reviews with checklists and ensure compliance with customer requirements.

Link and review existing Things Gone Wrong/Right to reduce risks in the early phases.

Track quotation versions, customer negotiations, and linked LOI/PO milestones.

Maintain version-controlled documentation for project scope and deliverables.

Define the initial product vision and scope based on market and business objectives.

Gather insights into market demand, competitors, and trends to guide design direction.

Capture customer needs and expectations to align product goals.

Compare with industry standards and competitor products to identify opportunities.

Evaluate technical and business feasibility before proceeding.

Maintain a structured checklist for PPAP submissions with automated document linking.

Digitally manage audit schedules, findings, and closures across all validation stages.

Manage Measurement System Analysis (MSA) and Statistical Process Control (SPC) reports for critical parameters.

Document pilot production runs, customer feedback, and approval statuses.

Ensure customer-approved PSW with supporting documentation and review history.

Manage engineering change notices and in-process changes with termination protocols.

Log non-conformances and corrective actions using 8D methodology and real-time tracking.

Run intensive checks for high-risk parts with real-time defect dashboards.

Get complete APQP visibility with live dashboards and export-ready reports. Track KPIs, monitor document readiness, and make faster decisions with data at your fingertips.

Track the real-time progress of each APQP phase with visual indicators and alerts, ensuring timely completion and better control.

Monitor essential metrics like Time-to-Market, First-Time-Right (FTR), and cycle times to drive performance and accountability.

Quickly assess which documents are ready or pending across APQP gates to ensure compliance with IATF and customer audits.

Dive into detailed reports for each part to evaluate performance, delays, quality issues, and process bottlenecks.

Generate and download formatted reports for internal reviews, customer meetings, and third-party audits in just a click.

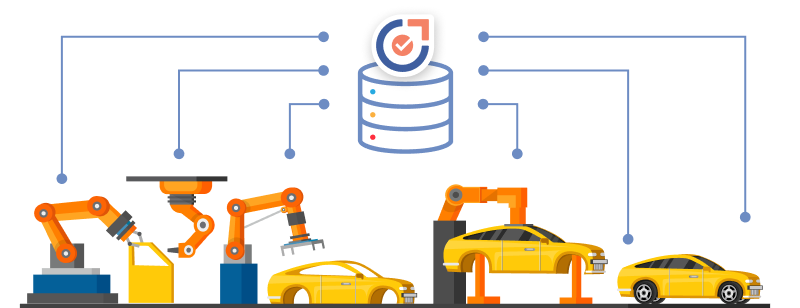

Protrak integrates effortlessly with ERP, MES, QA systems, and supplier portals to ensure your APQP data flows without friction across departments and tools.

Connect with leading ERP systems like SAP B1, Oracle, and others to synchronize part data, orders, and timelines across platforms.

Import supplier data and BOMs via Excel or API to streamline sourcing, reduce duplication, and maintain version accuracy.

Ensure your teams always work with the latest documents using auto-versioning synced with drawing updates and revisions.

Enable smooth data exchange with shop-floor systems and quality tools to support real-time validations and audit trails.

Protrak transforms APQP from a checklist into a strategic advantage—reducing delays, improving collaboration, and ensuring you're always audit-ready.

Track every APQP milestone with alerts and dashboards to ensure no gate is skipped or delayed.

Automate document control, approvals, and reporting to cut admin overhead by 40–60%.

Enable cross-functional teams to work in sync with live updates, shared tasks, and centralized data.

Stay aligned with IATF 16949 and customer-specific requirements using audit-ready records and traceability.

Start with core workflows and expand as needed—Protrak adapts to your project size and maturity.

Use live dashboards and KPI tracking to make faster, data-backed decisions across every stage of APQP.

See how one of our automotive clients streamlined their APQP process, reduced admin effort, and achieved faster, first-time-right submissions - all with Protrak's low-code platform.

Protrak empowers your team to digitize the full APQP lifecycle—from RFQ to SOP—with real-time collaboration, automation, and audit-ready workflows. Start faster, scale smarter, and deliver better.